Students weld together a new club

It was a spark of an idea that forged a new campus club.

A year ago, four engineering technology students were taking the class foundation of metals that included a brief training program for undergraduate students to learn how welding is used in manufacturing.

They knew they wanted more than welding 101 and started to build the framework of a new club.

“It was beneficial to have the class” said Jack Seeley, chapter president and a fourth-year manufacturing and mechanical engineering technology student from Cherry Valley, N.Y. “But we also wanted to learn more, to take advantage of the resources and equipment we have in our lab area.”

It seemed his peers across campus did as well.

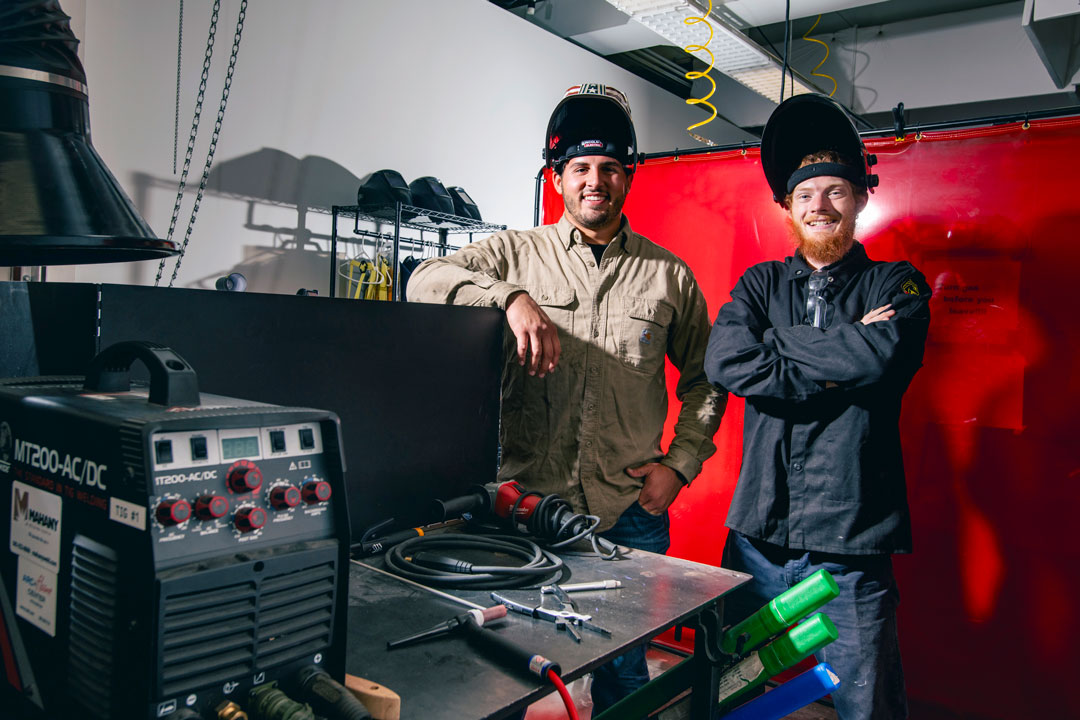

Within a year, Seeley and the others worked with Student Government, RIT’s College of Engineering Technology (CET) administration and faculty member Richard Roe to establish the new organization. It became one of the first student chapters of the American Welding Society’s Northeast District. RIT’s chapter has 50-plus active members and open to any major and experience level.

“We have a diverse team with a wide range of expertise. While many of us have an engineering technology background, our members also have backgrounds in game design, finance, art, mathematics and NTID,” said Lucio Tomassetti, chapter vice president, and a fifth-year manufacturing and mechanical engineering technology student from Fairport, N.Y. “We are working with the members from NTID to build our chapter in a way to make students who may be deaf or hard-of-hearing comfortable here.”

Liam Myerow/RIT

Members of the student chapter of the American Welding Society are learning how to weld for projects as varied as art to mechanical design.

Welding is the art of using high heat and pressure to mold, shape and secure metals. Those new to the process can be intimidated at first, but the group merged RIT’s general lab safety rules with specific welding safety measures to formulate a unique training program for new members.

“To enhance our training program, we’ve created a chief welder position. This person acts as lead trainer, with responsibilities that include ensuring lab safety, clean up, managing set up and teaching our next group of trainers,” said Tomassetti.

Seeley agreed: “We are constantly trying to improve and retrain our members, especially the newer members with less experience. We can start them on smaller projects so that they can learn what welding sounds like, what it feels like, how the helmet reacts, how it feels to wear different types of gloves and getting that person to feel comfortable with welding.”

The path to formalizing the student chapter was paved through help by alumnus Michael Krupnicki ’99 (MBA), a longtime supporter of RIT and its students, particularly those on the Baja, Formula and Hot Wheelz performance teams. Students learned how to weld at Arc & Flame, his business in Rochester. Krupnicki also provided much of the state-of-the-art equipment found in CET’s labs and in campus machine shops.

The connection to Arc and Flame locally as well as the national society provide multiple opportunities for chapter members to participate in local, regional and national programming, including student design competitions.

“For the current academic year, we are arranging a series of programs with local professionals. These sessions are designed to supplement our classroom learning and will cover a variety of practical skills, including designing with welding standards and fundamentals of business ownership,” said Tomassetti. Programs will focus on crucial skills, like improving interpersonal communication for project management and delivering effective presentations to clients.

Seeley agreed: “These things can help students become successful welding engineers and more confident project leaders.”

Latest All News

- RIT faculty member and students create peace art installation at Woodstock siteThe rolling Bethel Woods hills that once hosted the iconic 1969 Woodstock music festival now holds a new architectural tribute to peace. The Peace Pavilion, designed and built with the leadership of RIT architecture Professor Amanda Reis, invites visitors to pause, reflect, and immerse themselves in the legacy of a site that continues to symbolize cultural change. Reis, in her second year as a faculty member in the Golisano Institute for Sustainability’s Department of Architecture, partnered with longtime collaborator Eduardo Aquino of the University of Manitoba to submit a proposal to BuildFest 2: Peace Rises, a part of the Bethel Woods Art & Architecture Festival. The event, held Sept. 10-14, called on university professors to create “peace structures” of varying scales. Their submission, entered under their research and design practice AREA, was selected for the largest commission. “It was a real honor to be selected,” Reis said. “We saw it as an opportunity to combine design innovation with sustainability and to involve students in a transformative learning experience.” Set against the backdrop of Filippini Pond and an adjoining forest, the pavilion occupies an Instagram-worthy location on the Bethel Woods grounds. The pavilion’s form was inspired by the yin-yang symbol, a representation of interconnected opposites and balance. Reis and Aquino reinterpreted it into a cubic structure that offers a cocoon-like feel, while also offering spectacular views. Youngjin Yi RIT architecture students gained hands-on experience assembling prefabricated panels for the Peace Pavilion. Those visiting the structure will step into a light-filled space whose walls are inscribed with phrases curated from poetry, literature, and music. Some lyrics also come directly from Woodstock-era artists, a connection to the area’s past. Western Red Cedar was chosen as the primary material because of its beauty and resilience. The material strengthens over time, meaning the Peace Pavilion could endure for years. “Many of the BuildFest structures are temporary, but we wanted to increase the longevity of the Peace Pavilion,” Reis said. “The material gives it that possibility.” Reis emphasized that the project’s success was the result of many minds. While Reis and Aquino established the design, the project became a hands-on experience for RIT architecture students. The project served as an early design-build exercise for Reis’s Architecture Studio course, a master’s architectural design class that typically emphasizes theoretical projects. The Peace Pavilion offered the students a rare chance to see ideas translated into reality. The student team included Noah Baldon, Maddy Bortle, Anna-Leigha Clarke, Ryan Denberg, Sydney Fox, Gabriela Hernandez, Gil Merod, Mackendra Nobes, Julia Resnick, and Youngjin Yi. “The collaboration exposed students to the full cycle of design-build, from concept to construction,” Aquino said. “They encountered unexpected challenges and learned how to improvise solutions during installation, which is where the deepest learning often happens.” In addition to the student team, staff from the SHED—Michael Buffalin, Jim Heaney, and Chris Vorndran—played a key role in fabricating the engraved cedar boards, before it made the four-hour trek to the Catskills. Ralph Gutierrez, an architectural intern, also contributed to the design development, while Yi captured photography throughout the process. “All of the dimensional wood was fabricated at 10-foot lengths to minimize waste, and the design required tight tolerances that pushed us to be meticulous during assembly,” Aquino said. “Those details emphasized the balance between sustainability and craftsmanship.” Youngjin Yi Inside the Peace Pavilion, engraved phrases line the cedar walls, which include lyrics from popular Woodstock performers. During the build, Reis mentioned that a couple who had attended Woodstock stopped by in their original festival T-shirts, eager to step inside the new structure. The pavilion offers potential for several outdoor activities. “I can imagine people reading, meditating, or just waiting for friends to finish kayaking or swimming nearby,” Reis said. “As architects, we can anticipate some uses, but the most exciting thing is what we can’t predict.” Fox, an architecture graduate student from southern Maine, said the entire process taught her important lessons. “I see architecture as a tool that can bring people together, communicate ideas and stories, and challenge the status quo,” said Fox. “Building this Peace Pavilion with others helped me see the power of collective effort and how creating something together can forge meaningful bonds between people, giving a project even more significance beyond its final result.”

- William H. Sanders installed as RIT’s 11th presidentRIT will become a destination not just for students but for ideas, Bill Sanders said as part of formal ceremonies to install him as RIT’s 11th president. The university, he said, will be a place where breakthroughs in artificial intelligence, sustainability, and cybersecurity are born; where artists and technologists co-author the future; that graduates leaders prepared for careers that don’t even exist yet; where interdisciplinary research tackles real-world problems; and where the global footprint expands while the commitment to Rochester is deepened. “None of what we aspire to do together can be done without passionate people,” Sanders said. “We have a beautiful campus and the buildings and Tiger Athletics facilities that we have built in the last five years are best in their class. But I believe fundamentally that people are what drives RIT.” Carlos Ortiz/RIT Andreas Cangellaris, founding president of NEOM University in Saudi Arabia, served as keynote speaker at the ceremony. Hundreds of people, including delegates from 42 universities and state and community leaders, attended the tradition-filled ceremony on Sept. 26 at Gordon Field House and Activities Center. Hundreds more watched online. In his inaugural remarks, Sanders announced that RIT has secured gifts to establish five new endowed professorships, adding to the 49 that exist today. He outlined progress on the development of RIT’s new strategic framework, which he calls a shared ambition to build a university that is more inclusive, innovative, and interconnected than ever before. “As we stand at the threshold of a new chapter, I see a university that is not only ready for the future—but ready to shape it,” he said. Sanders was officially installed as president by Susan Puglia, chair of the RIT Board of Trustees, and vice chairs Susan Holliday ’85 (MBA) and Frank Sklarsky ’78 (business administration accounting). They presented him with the Presidential Collar of Authority, created in 1983 by the late Hans Christensen, the first Charlotte Fredericks Mowris Professor of Contemporary Crafts in the School for American Crafts. Andreas Cangellaris, founding president of NEOM University in Saudi Arabia, served as keynote speaker at the ceremony. Cangellaris and Sanders worked together at the University of Arizona and the University of Illinois at Urbana-Champaign. Cangellaris said Sanders is a natural leader who encourages cross-disciplinary collaboration and builds trust. Elizabeth Lamark Bill Sanders delivers remarks at the ceremony marking his inauguration as 11th president of RIT. Those traits, he said, are especially valuable now because of the potential and promise of artificial intelligence. Universities must rethink how they teach and learn, research and discover, and inspire and innovate. “To meet the moment, we need leaders who are wise, courageous, visionary, collaborative, and inspiring — leaders we can trust to bring the university community and all its stakeholders together, to comprehend the challenges and propose and advance the right path forward,” he said. “Bill Sanders is that leader, for this very moment.” Inauguration events also included faculty presentations, a panel on the future of higher education, campus tours, and a picnic with students. Sanders has nearly 40 years of experience in higher education, having most recently served as the Dr. William D. and Nancy W. Strecker Dean of the College of Engineering at Carnegie Mellon University in Pittsburgh from 2020 to 2025. He started at RIT on July 1. Read the full text of President Sanders’s inauguration remarks.

- RIT announces creation of five new endowed professorshipsThe creation of five new endowed professorships, together valued at $15 million, was announced Sept. 26 during the inauguration of the university’s 11th president, Bill Sanders. “Endowed professorships are important vehicles to retain and recruit our best faculty, formally and publicly acknowledge their excellence, and provide discretionary funds to allow them to take risks in research, enhance their teaching, and inspire students,” said Sanders. The new endowed professorships are: The Budington Family Professorship, which will support a faculty member in the College of Engineering Technology, is funded by Board of Trustees member Jonathan Budington ’91 (graphic communications) and his wife, Susannah Budington, to retain and recruit top faculty. The Jeffrey K. Harris Professorship will support a faculty member who exhibits multidisciplinary strategic thinking to solve important research challenges and advance RIT’s unique approach to multidisciplinary education in ways that are important to the university’s mission. It is funded by Jeffrey Harris ’75 (photographic sciences), past chair of RIT’s Board of Trustees, and his partner, Joyce Pratt, chair of RIT’s College of Liberal Arts National Council. The Ludwick Family Professorship will support the university’s strategic objective of recruiting and retaining distinguished scholars and teachers. It is funded by Worth Ludwick ’78 (MBA); her husband, Andy Ludwick; and their family, via the Santa Rita Foundation. The Frank and Ruth Sklarsky Professorship will initially support a faculty member whose research focus is in artificial intelligence, while future appointees will address critical emerging topics in science and technology. It is funded by Frank Sklarsky ’78 (business administration accounting), vice chair of RIT’s Board of Trustees, and his wife, Ruth Sklarsky. The Leo C. and Margaret J. Williams Professorship will support a faculty member in the College of Science. It is funded by Anna Williams, who is the mother of Molly Roesch, a 2023 graduate of RIT’s chemistry program, to honor her parents and Roesch’s grandparents. “Great universities are built by visionaries—faculty who imagine, create, and innovate—and by donors whose generosity makes that work possible,” said Phil Castleberry, vice president for University Advancement. “Endowed professorships unite these two forces, giving faculty the support to pursue bold ideas and students the chance to learn from world-class scholars. We are deeply grateful to our donors for investing in people, in discovery, and in the future of RIT.” Over time, these professorships will be awarded to current or new faculty based on their demonstrated academic excellence. Each of the new professorships, once approved by RIT’s Board of Trustees, will be endowed at $3 million, for a total of $15 million. RIT now has 54 endowed professorships.

- University leaders gathering for inauguration tackle important questions facing academiaUniversity presidents and leaders from across academia gathered in Rochester to discuss the rapidly shifting landscape of higher education. The distinguished experts noted how universities at the center of this change—including RIT—can use headwinds as opportunities to propel forward. Elizabeth Lamark Sin Min Yap, left, vice president of strategy for Synopsys, Inc., moderated the panel on the future of higher education. The event, called RIT in Conversation, was part of the inauguration of RIT’s 11th president, Bill Sanders, on Sept. 26. The program featured a panel where academic leaders shared their thoughts on some of the most important questions facing higher education today. The panel included:Sin Min Yap, vice president of strategy for Synopsys, Inc., as the panel moderator Gilda Barabino, former president of Olin College of Engineering Andreas Cangellaris, founding president of NEOM University W. Kent Fuchs, president emeritus of University of Florida James Garrett, provost and chief academic officer at Carnegie Mellon University Sarah Mangelsdorf, president of University of Rochester. Cangellaris discussed how universities must balance preparing students for jobs that don’t yet exist with the traditional mission of preparing students for careers in established professions. “Universities should continue to be engines of knowledge creation,” said Yap. “At the same time, universities can use that knowledge to create a positive impact in society, preparing students to be leaders in professions that are evolving rapidly or have yet to be created.” Garrett addressed the value of a university education. He said that it’s about preparing young people to be productive contributors of society, with a global and interdisciplinary mindset. He also remarked that universities teach how important it is to continue to learn how to learn. “This is something I tell my students,” added Yap. “The mind is like a parachute—it only works when it’s open.” Elizabeth Lamark Jeyhan Kartaltepe, associate professor in RIT’s School of Physics and Astronomy, explained her research with the James Webb Space Telescope at the inauguration event. When discussing the Rochester region’s 19 colleges and universities, Mangelsdorf remarked how higher education has taken on the mantle as an innovation and employment driver in the area. She also highlighted RIT and University of Rochester’s many collaborations and partnerships, including joining New York state’s Empire AI consortium—a partnership of leading public and private universities to advance responsible artificial intelligence—and the development of the Rochester Quantum Network, where researchers are using single photons over fiber-optic lines. In closing, the panel offered advice to RIT’s leadership about its future role in higher education. Barabino advised Sanders to value every member of RIT’s community and stay true to the university’s values. On a personal note, Fuchs wished great joy to the new president and his family. The program also featured five RIT professors who are pushing research and inspiring students. Faculty members included:Denis Cormier, the Earl W. Brinkman Professor of Industrial and Systems Engineering and founder and director of the New York state-supported Additive Manufacturing and Multifunctional Printing (AMPrint) Center. He discussed a few projects that excite him the most, including 3D printing drones and developing a high-speed metal inkjet 3D printing process. Jeyhan Kartaltepe, an astrophysicist in the School of Physics and Astronomy. She talked about studying the history of the universe and leading the largest program accepted for the first two years of observations with the James Webb Space Telescope. Ashique KhudaBukhsh, assistant professor in the Department of Software Engineering and affiliate of the ESL Global Cybersecurity Institute. He discussed using artificial intelligence for social impact and how his research is helping strengthen the safety guardrails of large language models. Josh Owen, the Vignelli Distinguished Professor of Design and director of the Vignelli Center for Design Studies. He shared how keeping a foothold in the educational and professional sectors is important for preparing students who can tackle real-world problems. Thomastine Sarchet-Maher, assistant professor in the Department of Deaf Education at the National Technical Institute for the Deaf (NTID). She spoke about her experience leading deaf education development projects in Southeast Asia and Africa.

- Student picnic begins inauguration festivitiesFood, music, trivia contests, and plenty of selfies were featured at a free student picnic Thursday outside the Gene Polisseni Center to kick off two days of events for the inauguration of Bill Sanders, RIT’s 11th president. “It’s great to see you all,” Sanders said. “I’ve quickly found in the 10 or 11 weeks that I’ve been here that what makes RIT really special is that sense of community. Wherever you’re from, whatever you’re studying, whatever your likes are, you can find a place here. And that’s really special to me.” Sanders, along with his wife, Emily, and their dog, Ollie, enjoyed music from the Brick City Singers and Proof of Purchase a capella groups. Sanders met with many students who came up to him after his remarks. Carlos Ortiz/RIT RIT President Bill Sanders met with students, including Reese Fernandez, during a picnic Thursday. Mickey Polito, a fifth-year software engineering major from Webster, N.Y., wanted a selfie. Sanders asked Polito what his plans are after he graduates at the end of this semester. Polito said he was taking a job with More Vang, where he had a co-op. “He’s so accessible, extraordinarily nice, extraordinarily kind,” Polito said. “I’m so glad he’s meeting with students.” Reese Fernandez, a third-year design and imaging technology major from Austin, Texas, asked Sanders what he likes about RIT. “There are so many possibilities here,” Sanders said. “I love all the majors and courses RIT has to offer.” Tyler Mahan, a fourth-year finance major from Calgary, Alberta, was one of four members of the RIT men’s hockey team who posed with Sanders after his remarks. “I came out here just to meet the president and invite him to one of our games,” Mahan said. “He’s awesome and seems to be a great guy. We had a great chat.” The inauguration ceremony begins at 2 p.m. Friday in the Gordon Field House and Activities Center.

- RIT-created virtual reality game ‘Changeling VR’ arrives on SteamMore than 300 RIT students have published Changeling VR, a new narrative mystery game on Steam. The virtual reality (VR) game is now available to download for free on the online game platform for early access. The community-built game is five years in the making. It has included students and faculty from RIT’s Golisano College of Computing and Information Sciences and the College of Art and Design. For many students, working on the game counted as a key co-op credit for their degree program. In Changeling VR, players take on the role of a detective who can see people’s thoughts and memories. Using these mystical powers and skills of deduction, players must work with a family to discover what is wrong with their baby. Each member of the family has their own unique level, making it like five VR games in one. For example, the mother’s level is ethereal, like floating through space. With the brother, players slingshot through a level in the style of his sketchbook. The father—an engineer—is faced with a series puzzles. Changeling VR Elouise Oyzon, associate director of the School of Interactive Games and Media (IGM), came up with the idea for Changeling VR while watching “Murder on the Orient Express.” “In detective stories, you interview all these people, and they give you their version of truth in flashbacks,” said Oyzon. “The VR genre is perfect for this because it can really give you a point of view. And in this game, we can give each family member’s memory a totally different vibe and aesthetic.” The project began during the COVID pandemic, when Oyzon noticed that many co-op opportunities in the industry were being put on hold. She had the idea for the VR game and thought it could be a great experiential learning experience in agile development. “Typically, IGM students on their first co-ops might work in quality assurance or user experience, but they don’t always get to do level design, narrative, or sound composition,” said Oyzon. “At the Changeling studio, they get to do the things they have been doing in class and even take on new roles.” Students on co-op with the Changeling studio worked full time and had the option to work remotely. Documentation was key for development because new co-op cohorts came in each semester. For Julian Alvia, a fourth-year game design and development major, the co-op was an opportunity to learn Unreal Engine, as opposed to the Unity game engine he uses in the classroom. As a team lead, he oversaw development and fixed bugs. Later, as a producer, he ran the studio’s daily stand-up meeting and weekly milestone meetings. “It was a challenge allowing people to be creative, while also meeting deadlines within the scope of what we wanted to do during our cohort,” said Alvia, who is from Waterbury, Conn. “It was rewarding learning how to be a leader and now that’s the direction I want to focus my career.” Changeling VR Alvia added, “Having a published game to your name is good to put on résumé and show future employers.” Kyle James still uses the skills he learned from working on Changeling VR. He graduated from the Combined Accelerated BS/MS in game design and development in 2024 and now works as a project a project manager for the STNDRD Fitness app. “As a co-op, being able to manage 80 people across disciplines was a huge learning process,” said James. Right now, the game is in Steam Early Access—a unique development model that allows games to be played as they progress towards a full release. The team plans to continue development for about 18 months. Four out of the seven eventual levels can now be played. Players speeding through the game can finish it in about 40 minutes, while others looking to explore can take hours. The game is published through RIT’s MAGIC Spell Studios. Download Changeling VR for free on Steam.