Adding self-repair capabilities builds strength, durability, and could reduce part replacement processing

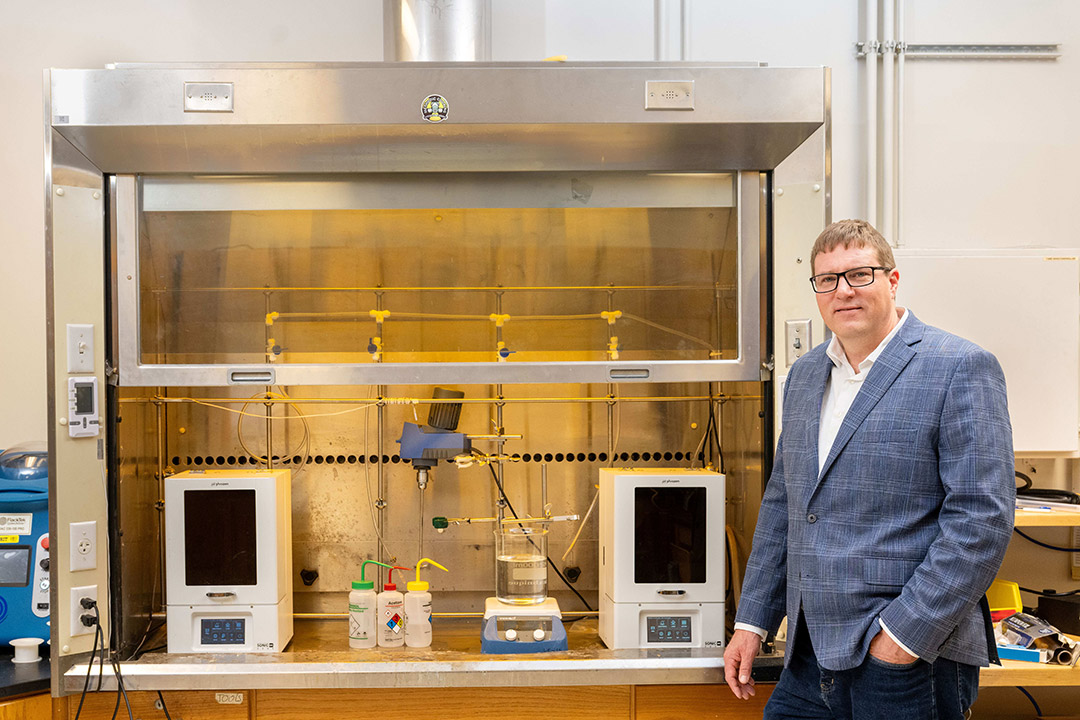

Peter Schuck/RIT

Christopher Lewis, a faculty-researcher in RIT’s College of Engineering Technology, developed a self-healing materials solution to improve 3D printing.

Self-healing materials are being developed by RIT researchers to further improve additive manufacturing, specifically 3D-printed products, to make them stronger and more resilient.

Christopher Lewis and members of his research team developed a stimuli-responsive photopolymer solution—liquid resins similar in texture to superglue—that once printed exhibits the ability to self-heal when damaged, and through the lithography process, these liquid resins solidify selectively, layer-by-layer.

There is a lot of interest today in materials that can heal, or self-repair, themselves. In 3D printing, the ability to build more reliable parts that have these healing actions can benefit multiple industries and provide cost savings. Companies can rely more confidently on the strength of materials being used for high-precision equipment such as printed electronics, soft robotics, or prosthetics for the aerospace, automotive, and biomedical fields, said Lewis, an associate professor and Russell C. McCarthy Endowed Professor in RIT’s College of Engineering Technology.

“When you break a bone, or cut yourself, we take it for granted that there is a self-repairing mechanism that allows for bones or skin to rejuvenate themselves, at least to some extent,” said Lewis. “We also learn that it is not true for synthetic materials or man-made objects. And our work in self-healing materials is a futuristics look at how we can develop systems that mimic those natural material properties.”

Peter Schuck/RIT

Christopher Lewis, left, discussed the cellular nuances related to the self-healing resins with BS/MS student Kaia Ambrose. Ambrose is part of the team focused on shape memory behavior.

Over time, 3D-printed objects can crack, particularly those used in load-bearing applications. This is worsened by the fact that many of the materials used in 3D printing are inherently brittle. Without intervention, the structures can fail. The team discovered that by combining a thermoplastic agent with an ultraviolet-curable resin enables a stronger 3D-printing process, while also creating a blend that reinforces cracked areas.

“It makes the material much stronger than it used to be. One of the problems with these soft, elastomeric materials is that they are traditionally weak. And it also engenders another type of property—shape memory behavior, and we are just starting to focus our efforts on better understanding this behavior,” said Lewis.

At the forefront of this work for several years, Lewis received funding from the U.S. Department of Defense and partnered with scientists in RIT’s AMPrint Center to test how self-healing materials supplement 3D-print processes. He and co-authors Vincent Mei and Kory Schimmelpfennig, RIT doctoral students, detailed the work in several journals including ACS Applied Polymer Materials, Polymer, and a recent issue of 3D Print Industry. Each highlights the team’s focus on the UV-vat polymerization of this liquid resin system.

The challenges, he said, are in regulating the viscosity of the reactive resin, and ensuring all materials are soluble and light sensitive.

“The approach we have taken is one where we have a mixture of two different things. We have our photoreactive, thermosetting polymer that once cured becomes a soft rubber. To this, we also add a thermoplastic healing agent. We were able to get light to pass through the system, and we achieved that by utilizing polymerization induced phase separation (PIPS). It is a process where the thermoset and thermoplastic materials separate during curing,” he said. “That is key to this whole thing.”

PIPS is a single, segmented function where an optically transparent liquid allows light to pass through. By curing the UV resin, the thermoplastic phase separates. Lewis compared that final phase-separated structure to a lava lamp that changes as it is lit or heated. It is similar with the polymers that transform as they are integrated with the 3D-print as each layer is cured.

“Earlier work on thermoplastic polymer blends that are able to be processed using conventional techniques like injection molding or extrusion suggested that it was that phase separation that seemed to be driving the self-healing behavior of those systems. That understanding led us down this path of experimentation with this same healing agent and photo reactive polymer system, and then, a little bit of luck,” said Lewis.