New design platform allows engineers to think more sustainably

- Researchers at RIT’s Golisano Institute for Sustainability have developed PhoenixDFR, a software tool that helps engineers design products with remanufacturing in mind.

- The tool uses real-world industry data to flag design issues and guide improvements through web and CAD-based platforms.

- The team worked closely with companies from multiple sectors, including heavy equipment, HVAC systems, and automotive.

Brian Hilton, principal investigator (PI) and engineering manager at Golisano Institute for Sustainability (GIS), has been searching for solutions to an increasingly disposable society. When his 9-year-old refrigerator started failing, the repair quote came in at a price that was higher than the price of a new unit.

“There was a leak in the line somewhere,” Hilton said. “From an engineering standpoint, that should have been an easy fix. But the repair technician told me that given the difficult access to the lines and the lack of system modularity, I’d be better off buying a new one.”

That experience reflects a larger, global problem in product development—most products are not designed with longevity in mind and may contain features that make a second life technically or economically unfeasible.

To help solve this problem, engineers at GIS have developed a new software platform to help manufacturers design products that are easier to remanufacture. The tool, named PhoenixDFR, helps engineers think about sustainability earlier in the design process. The tool works both as a web app and as plug-ins within popular computer-aided design (CAD) software.

PhoenixDFR helps engineers evaluate product parts for attributes that could hinder remanufacturing, such as excessive wear, corrosion, or general material loss. The tool then guides users through a step-by-step decision process that highlights design fixes and workarounds, then generates a detailed report with screenshots, design suggestions, and a performance score based on a custom scoring system built by the team.

“We're not trying to tell the design engineer what to do,” said senior engineer Frank Zelinger. “A design engineer and a product manager will still weigh things like cost into the equation, but now you've given them another piece of information to think about.”

The system draws on a growing database of 25 remanufacturing failure modes and hundreds of design rules, collected from industry papers, textbooks, and during site visits to different manufacturers.

“They opened their doors and let us basically go dumpster diving at the end of a remanufacturing line,” Hilton said. “We asked a ton of questions and got insights that go beyond what you’d typically find in a concise journal article.”

Hilton said the team visited five sites across the country and worked closely with companies from multiple sectors, including heavy equipment, HVAC systems, and automotive.

“Having them be open to sharing pre-competitive information was a very important part of this,” he added. “It’s been a strong collaboration, and we couldn’t have done this without industry in the room.”

The team working on this project consists of Hilton, Zelinger, and senior engineer/Co-PI Scott Nichols, who leads software development. They were aided by a group of RIT co-op students, including and former co-op student and 2023 graduate Miko Buenk and third-year computer science student Jared Randall. They helped quantify environmental impacts of remanufacturing and address cybersecurity of the tool for use in industry settings, respectively.

PhoenixDFR was built with heavy equipment and industrial components in mind, but the team sees opportunities to expand into other product sectors—including consumer electronics, transportation systems, and appliances like Hilton’s refrigerator.

“There’s no reason why the principles behind this tool can’t apply to everything from kitchen equipment to laptops,” said Hilton. “Any time you can extend the life of a product, you’re getting more value out of the materials, energy, and labor that went into it.”

Although still in beta testing, PhoenixDFR is already generating strong interest among manufacturers. The team is exploring commercialization options.

“We want to push the envelope,” Hilton said. “We want people to think more about circularity and think more about sustainability and how to integrate that into product development. But today, let's work on remanufacturing.”

The tool began development in 2023, thanks to $1.96 million in grants from the REMADE Institute, a public-private partnership and Manufacturing USA innovation institute funded in part by the U.S. Department of Energy and Empire State Development.

This material is based upon work supported by the U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy (EERE) under the Advanced Manufacturing Office Award Number DE-EE0007897 awarded to the REMADE Institute, a division of Sustainable Manufacturing Innovation Alliance Corp. In addition, RIT received funding, in part, from New York State Empire State Development under grant #AC118 that supported the work on this project. The views expressed herein do not necessarily represent the views of the U.S. Department of Energy, the United States Government or New York State.

Latest All News

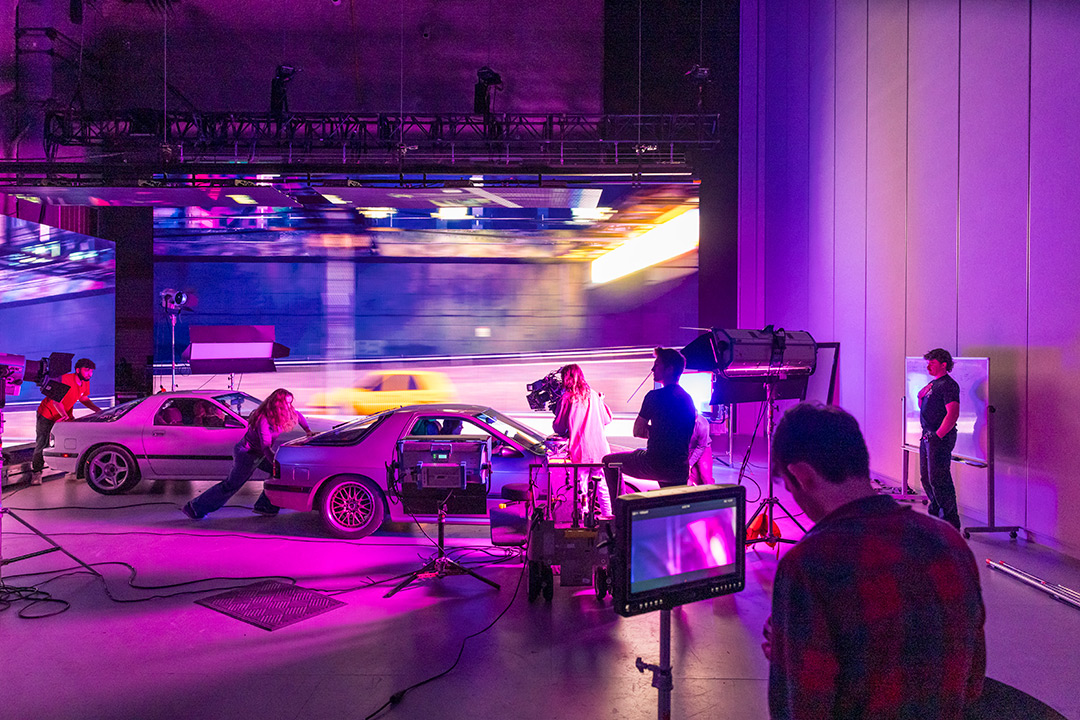

- ‘The Hollywood Reporter’ names RIT as a top film school in the U.S. for second yearAccomplished alumni, creative technology research, and interdisciplinary program offerings set RIT’s School of Film and Animation (SOFA) apart from others on The Hollywood Reporter’s 2025 top film schools list (see pages 86-87). RIT was ranked number 22 this year, a leap ahead from the school’s rank in 2024. The Hollywood Reporter, an entertainment trade publication based in Los Angeles, cited RIT alumni in the industry—such as Chris Edwards ’97 (film production), founder and chief executive officer of visualization studio The Third Floor, and John Traver ’11 (motion picture science), co-founder and creative technologist of editing platform Frame.io—as a key indicator of the school’s success. Quinn Freidenburg New school director Ricky Figueroa emphasized that the creative minds and hard work of students, faculty, and staff is what has earned RIT’s recognition as a top film school. The publication wrote, “Finding future collaborators and a strong alumni network continue to be some of the biggest selling points for film schools.” The Hollywood Reporter also considered RIT’s facilities like MAGIC Spell Studios, student access to industry-standard equipment, and endowments supporting the film school when granting the ranking. Ricky Figueroa, director of SOFA, shared that a recognition like this highlights what’s most valuable in the school: the work of students, faculty, and staff. “This is something that makes our community excited and inspires us for the future. There is nothing better than seeing our students and faculty being recognized among the best in the nation,” he said. Figueroa was recently appointed director of SOFA after teaching in the school for nearly 20 years. He previously served as director of the undergraduate motion picture science program. In February 2025, he was named the inaugural John Traver Endowed Professor. Over the last year, RIT has been increasingly recognized as a top film school by publications like TheWrap, Variety magazine, and Animation Career Review. Becoming a leader amidst this increased visibility energizes Figueroa as he looks toward the future of SOFA’s program offerings. “The recognition has the potential to attract additional internal and external collaborations and project opportunities for our community, which are essential for the continuous growth of our school,” said Figueroa. “It pushes us to keep moving forward and strive for even greater heights.” Those hands-on experiential learning opportunities continue to prove invaluable for RIT students. Programs like RIT in LA, which is set to welcome its fourth cohort this fall, create opportunities for students to live, learn, and work in Los Angeles for a full semester. This year, RIT in LA expanded its offerings to include a track in games in addition to the tracks in film and animation and transmedia storytelling. Other experiential learning opportunities, like continued involvement with the Coca-Cola Refreshing Films program and the recently established student exchange program with the Film and TV School of the Academy of Performing Arts in Prague (FAMU), add to the value RIT offers to current and prospective students. Go to RIT’s School of Film and Animation website to learn more about its program offerings.

- State renews AMPrint Center’s contract to continue advancing 3D-printing technologiesRIT’s AMPrint Center recently received a 10-year renewal contract from New York state to continue development of next-generation 3D-printing processes, materials, and applications. The renewal funding will be distributed in two five-year increments, and the first allotment of $5 million will be used beginning this fiscal year. The AMPrint Center was established in 2015 to help position New York state as a global leader in 3D-printing technologies through industry, government, and academic partnerships. New start-ups have matured in the state through AMPrint’s research, training, and support capabilities. Its team has also contributed technology to improve how high-performance materials, including metals and carbon fiber composites, are being used in 3D-printing applications, said Denis Cormier, director of the AMPrint Center. “The AMPrint Center is helping to breathe new life into this region’s world-renowned printing industry by applying its expertise to the rapidly growing 3D-printing universe,” said Cormier, the Earl W. Brinkman Professor of Industrial and Systems Engineering in RIT’s Kate Gleason College of Engineering. The center has an extensive range of high-tech 3D-printing equipment being used for research as well as hands-on educational and training resources for students, faculty-researchers, and corporate partners. According to Wohlers’ Associates, the global report on 3D printing and additive manufacturing stated that the industry grew from $5.1 billion in 2015 to nearly $22 billion in 2024. This renewal grant is a result of the integral work provided by AMPrint: to support and launch start-up companies and to help existing companies successfully adopt industrial grade 3D-printing and additive manufacturing technologies in real-world applications. For example, AMPrint is helping Rochester-based 3D printer company Impossible Objects develop a machine that produces ultra-strong and lightweight carbon fiber composite components. Impossible Objects recently installed what it refers to as the world’s fastest 3D printer, the CBAM-25 machine, in the AMPrint Center. The new printer becomes another in a series of high-end, high-tech—and very fast—3D printer assets at the university, and multiple funded projects are already underway at the AMPrint Center using this new carbon composite 3D printer. “There’s an acute need for high-speed 3D printers that can produce very strong, very light weight components for drones and other applications,” Cormier explained. Additional applications include the development of custom-made carrier boards for the soldering process used to make electronic circuit boards. With the newer, faster printing process, Impossible Objects’ capabilities reduce both time and cost to production. “This is a ground-breaking piece of industrial manufacturing equipment,” said Cormier. “If you visualize a digital printing press making magazines or newspapers, the paper is just flying through the machine. Now translate that into 3D printing; that is what Impossible Objects has done. They are using carbon fiber instead of paper. There isn’t any 3D-printing technology that touches this machine's print speed, while simultaneously making such high strength parts.” Beyond speed and strength, AMPrint has also been leading the development of a 3D printer that operates like an inkjet printer in which the ink is molten metal. Cormier recently received a $3 million Future Manufacturing Research grant from the National Science Foundation to bring this technology closer to commercialization. Specifically, the team is scaling up the speed of this printing technology and is also expanding the types of molten metals that it can print. They expect to see it in commercial use within the next five years. “I’m biased of course, but I believe that this metal 3D-printing technology has the potential to transform the way many metal parts are made. Instead of mass-producing parts that are shipped halfway across the world for storage in huge warehouses, it will be possible to locally print metal parts on-demand just before they are needed,” said Cormier. On campus, several 3D-printing classes are available for undergraduate and graduate students using the AMPrint Center's broad range of equipment to ensure there is a pipeline of skilled engineers that can incorporate 3D-printing technology into varied industries. These classes range from Introduction to 3D Printing and Personalized 3D Printing to Metal and Composite 3D Printing. Students are learning about 3D printing processes and applications through coursework, research projects, and internships with the AMPrint Center's industry partners. Companies can also use any of the different industrial-grade machines or provide prototype devices for testing before commercialization. The AMPrint Center is involved in a diverse range of other industry and government funding projects. A collaboration between RIT and Alfred University is underway to develop a novel technique for 3D-printing glass structures that can go from ultra-low to ultra-high temperatures without cracking or breaking. The center team is also helping a company to develop a 3D printer capable of producing full color customized dentures.

- Tiger Tutor Team prepares for second year with Rochester studentsLily Yengo loves math, kids, and fellow nerds. The fourth-year mechanical engineering student participated on the Tiger Tutor Team this past spring semester, working with accelerated fifth graders in the Rochester City School District to ensure they retain their love of math. This summer, Yengo is helping to enhance instructional materials—adding and testing new activities and problems-- and providing improvements to the overall process of recruiting and training new tutors for the upcoming academic year. Based in the industrial and systems engineering department, the Tiger Tutor Team began in the 2024-2025 academic year, and more than 60 RIT students tutored five eighth-grade classes and one group of talented fifth graders at three Rochester schools: Loretta Johnson Middle School, School of the Arts, and No. 12 School. The goal was to keep students in accelerated programs excited about, and engaged in, math, as well as improve passing rates for those taking the New York State Regents exams. “I love working with kids. I love math, I’m a huge nerd and so working with these super smart kids who are huge nerds—and I mean this in the most loving way possible—they were there because they wanted to be there. They wanted to learn algebra and trigonometry in their free time. So, we taught them,” said Yengo, who is from Skaneateles, N.Y. Yengo is currently on co-op in Rochester for the DDS Companies, creating base maps of underground utilities to be used in natural gas main installations. She assesses historical records and current photos to compile a map with all the necessary information above and below ground. Yengo talked about the tutoring work and her inspiration for teaching. What is the Tiger Tutor Team? And who were the students you worked with? It’s very new. Dr. Katie (industrial engineering department head Katie McConky) began a partnership with the Rochester City School District and invited engineering and math students to volunteer. She said if you like working with kids and if you like math you should be a Tiger Tutor, and I was like yeah… perfect! There were about 15 of us that worked with the fifth-grade students in groups of three or four. What are you doing this summer to support the program for the upcoming academic year? Sometimes it’s trial by fire and you just need to throw it together and see what works and what doesn’t. We didn’t have a curriculum per se, so my job now is to do that work so that next semester’s tutors are prepared. Everything will be ready. I may not have known how to teach someone the quadratic formula, but my job over the summer is to prepare a guide for the tutors with worksheets and answers, just to make everything more streamlined. Coming up with math problems on the fly is really hard. Why is work like this important for you, your peers, and the fifth graders? For me, at RIT, I am a student, I am there to learn and I’m trying to soak up as much calculus as I can, because it is really hard. But with the kids, it is such a different age demographic. It’s fun to talk to them and these kids are fun. As someone who grew up in public schools in situations similar to them, I loved learning and would have loved to have a program like this—a program to push the boundaries of what I knew. To succeed in something that challenging is rewarding—for them and for us. And you can tell that they know that is really hard, and that’s why they like it too. When we do algebra together, they are asking questions, talking to each other, they are showing each other their work, it is a bigger conversation. How did you prepare for fifth graders who want to take eighth-grade advanced math classes? I’ve got to shout out to my mom. She was a teacher her whole life, now she is a principal. I have always been around kids. I’ve gone to her classroom after school and hung out with her and whatever kids she was teaching at the time. I’ve taken a lot from her to do this job. We’ve probably talked about this job more than any other that I’ve had because she cares about algebra curriculums, that’s her thing. She loves teaching. I learned the most from my mom about this. To learn more The pilot year saw significant gains in mastery rates for students taking the Algebra Regents exam, according to the RCSD Department of Math. RIT’s Tiger Tutor Team is seeking additional tutors and is expecting to expand to include both fifth and sixth graders from School No. 12. The time commitment for tutors is approximately two hours per week. To get involved, contact Professor Katie McConky at ktmeie@rit.edu.

- Disney's ‘Phineas and Ferb’ co-creator to speak at Brick City WeekendDozens of events are planned—from sports, tours, entertainers, and music—for Rochester Institute of Technology’s Brick City Homecoming and Family Weekend Oct. 17-19. Thousands of the more than 150,000 RIT alumni and their families, as well as current RIT students, faculty, staff, and retirees, are expected on campus for the events. Emmy-winning animation veteran Dan Povenmire, co-creator and executive producer of Disney’s animated series Phineas and Ferb, will be this year’s Student Government Speaker. He voices the evil Dr. Heinz Doofenshmirtz on the series and has amassed more than 7 million followers on Tik Tok and Instagram. He is also creator and executive producer of Disney’s original animated superhero series Hamster & Gretel. With more than 25 years of experience in directing, storyboarding, and writing, Povenmire has worked on multiple critically acclaimed animated series including Family Guy, SpongeBob SquarePants, The Simpsons, Rocko's Modern Life, and Hey Arnold! His talk is scheduled for the afternoon of Oct. 18 in the Gordon Field House and Activities Center. Comedian, actor, and musician Craig Robinson is scheduled for Oct. 17. Currently executive producer and star of Peacock’s Killing It, he’s best known for his portrayal of Darryl Philbin in The Office. Men’s hockey vs. Clarkson is scheduled on Oct. 18 at Blue Cross Arena, and two women’s hockey games vs. St. Lawrence are planned in the Gene Polisseni Center. “From comedian Craig Robinson to Emmy-winner Dan Povenmire, hockey and family-friendly events, this year’s Brick City Weekend offers something for everyone,” said Lisa Stein, executive director for events and conferences at RIT. “It’s a fun and vibrant celebration that brings together the entire RIT community of alumni, students, faculty, staff, and families alike.” Tickets for all events will be available starting in August from the Brick City website.

- Studio 930 students create assistive solutions for real-world challengesGive teams of RIT students a design challenge, a 10-week deadline, and real clients in need of practical solutions, and they will rise to the occasion. Now in its 10th year, the interdisciplinary and collaborative Studio 930 program asks students to apply what they know, learn what they don’t, and design products that make life, or a single task, more efficient and accessible. Four teams presented their design solutions to clients from the Al Sigl Community of Agencies and Rochester Regional Health on July 16 in the SHED’s Brooks H. Brower Maker Showcase. Students working with the Al Sigl Community of Agencies designed:“Snuggo,” a wearable sensory toy/vest fashioned as a stingray to help calm children with autism spectrum disorder; and A freestanding, interactive play system to promote motor development skills. Teams assigned to Rochester Regional Health focused on projects to improve workflow obstacles identified by nurses and physical therapists in the health system. Their solutions included:A sturdy, but lightweight, medical bag with multiple compartments and a table to assist visiting home care nurses and physical therapists; and A mechanical bandage dispenser that opens the wrapper while keeping the gauze sterile—a task made difficult while wearing protective gloves. “Snuggo” team member Varun Varma, an MFA industrial design student from Mumbai, India, learned about bringing a concept to life. “It was really new to me because working with soft toys is something that requires a lot of sewing and using fabrics,” he said. “I’m used to conceptual projects, but this was manufacturing something physical, so that was very new to me, and I enjoyed it.” Noam Arenstein, a fourth-year mechatronics engineering technology major from Scarsdale, N.Y., applied to Studio 930 for the experience of working on a multidisciplinary team in preparation for entering the workforce. Later, he learned he could earn co-op credit from participating in the program, as well. Studio930 introduced Arenstein to the process of design thinking and prioritizing the needs and perspectives of the end user and other stakeholders. “I’ve never worked on a product that is tailored to other people’s concerns,” Arenstein said. “One of the new experiences for me was including empathy when it comes to design.” Supported this summer by the School of Individualized Study (SOIS), Studio 930 has its roots in the industrial design department. Stan Rickel, associate professor in the School of Design, started the program in 2015 to give industrial design MFA graduates client-driven work experience. When a couple of engineering students heard about the idea and joined the group, Rickels saw how Studio 930 could expand. “The enthusiasm of the students kept it moving,” Rickel said. “This year, we had 15 students in the program from five different colleges and eight different academic programs.” The collaborative, client-based program also draws like-minded RIT professors whose interests complement and sometimes overlap. Engineering professor Dan Phillips, for instance, helps recruit students and elicit college support. He also solicits and assesses challenges from participating community partners. The bandage dispenser designed for Rochester Regional Health is one example of students brainstorming concepts with advice and feedback from the client, a strategic partner in the RIT-RRH Alliance. Studio 930 is both a program and a community that revolves around collaborative and interdisciplinary teamwork focused on accessibility and healthcare, according to Dan Harel, the studio’s manager and adjunct professor of industrial design. Studio 930 operates from the SHED, giving students easy access to makerspaces, materials, and meeting rooms. The facility, which opened in 2023, provides a common space for the Studio 930 teams, which, in the past, had been scattered in workshops across campus. Offering the program in the SHED has made a difference in the quality of the students’ projects, Harel said. “You get bigger ideas when you have the room to spread out and play with different processes.” Proximity to different technology, from textiles to 3D printing, in one facility encourages creative thinking, he said. “We were able to generate more and quicker prototypes using materials that are available here, or that we purchased, and everything went faster,” Harel said. “The students were really inspired by the open environment and interactions with visitors. You know, people come and see what you’re working on, and it’s really encouraging to students.” Along with SOIS, Studio 930 was sponsored by the industrial design department within the College of Art and Design, the College of Engineering Technology, the Kate Gleason College of Engineering, and the Waldron Rise Foundation.

- App blends history, technology, and student talent in new tourism initiativeA collaboration between RIT and the Finger Lakes Visitors Connection is about to change how people experience local history in Ontario County, N.Y. The Finger Lakes Virtual Museum app—developed primarily by students and set to launch publicly this fall—is a digital storytelling platform that combines historical content with technology to create immersive visitor experiences. The idea began with Finger Lakes Visitors Connection, the county’s official tourism promotion agency, which wanted to add “more of the story” to historic markers across the region. Backed by a grant from New York State Empire State Development, the project was brought to RIT’s MAGIC Spell Studios to engage students in real-world development work. “This is exactly the kind of hands-on, real-world experience that students need,” said Diane Linnet, project director, business development and adjunct professor at RIT. “It’s not hypothetical. They’re working with clients, managing deadlines, solving creative and technical challenges, and seeing the direct impact of their work on the community.” A multidisciplinary team of students collaborated over the past year on everything from design and user experience to content creation, and included 2D- and 3D-digital storytelling, augmented reality, photo and video production, and location-based interactive activities. Provided RIT student Jason Salazar Tobar, who was augmented reality developer on the project, used the experience to reflect on the cultural impact of his work. When launched, the app will be accessible through a web platform and as a downloadable mobile app. Visitors to Ontario County will be able to scan QR codes on historic signs and access curated digital content that adds to each location’s story. Jason Salazar Tobar, a fourth-year individualized program major from Mount Kisco, N.Y., served as augmented reality developer, and used the project to continue exploring his interest in how emerging technologies can intersect with art, culture, and live performance. This past March, he and Max Stromfeld ’25 (graphic design) debuted a prototype of the app during a conference in Dubrovnik, co-organized by RIT Croatia. “This project gave me a whole new perspective on the museum world,” said Salazar Tobar. “I started thinking more like a curator and asking deeper questions like, ‘What are we trying to make the user feel?’ It pushed me to go beyond just making something cool and really considering the cultural impact of the experiences I was building.” Linnet added that projects like this are helping to enrich the region’s tourism while preparing students for industry. “We’ve already seen students go into interviews where this project was a major conversation point,” she said. “That’s the kind of return on investment that benefits everyone—students, universities, and communities.”