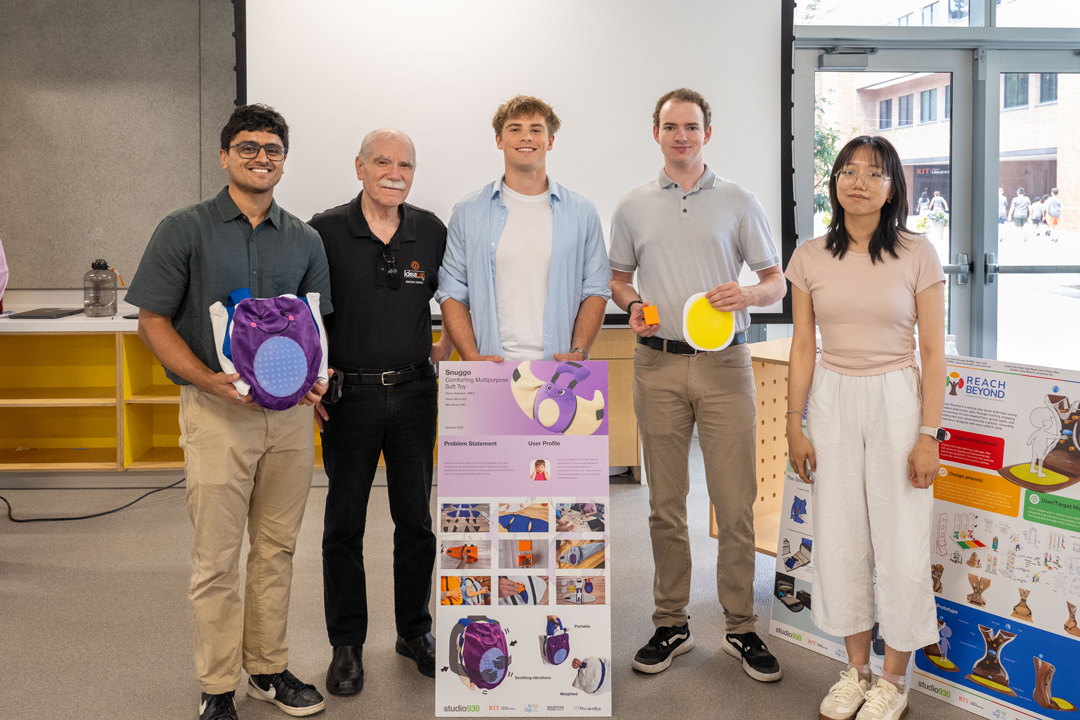

Studio 930 students create assistive solutions for real-world challenges

Give teams of RIT students a design challenge, a 10-week deadline, and real clients in need of practical solutions, and they will rise to the occasion.

Now in its 10th year, the interdisciplinary and collaborative Studio 930 program asks students to apply what they know, learn what they don’t, and design products that make life, or a single task, more efficient and accessible.

Four teams presented their design solutions to clients from the Al Sigl Community of Agencies and Rochester Regional Health on July 16 in the SHED’s Brooks H. Brower Maker Showcase.

Students working with the Al Sigl Community of Agencies designed:

- “Snuggo,” a wearable sensory toy/vest fashioned as a stingray to help calm children with autism spectrum disorder; and

- A freestanding, interactive play system to promote motor development skills.

Teams assigned to Rochester Regional Health focused on projects to improve workflow obstacles identified by nurses and physical therapists in the health system. Their solutions included:

- A sturdy, but lightweight, medical bag with multiple compartments and a table to assist visiting home care nurses and physical therapists; and

- A mechanical bandage dispenser that opens the wrapper while keeping the gauze sterile—a task made difficult while wearing protective gloves.

“Snuggo” team member Varun Varma, an MFA industrial design student from Mumbai, India, learned about bringing a concept to life.

“It was really new to me because working with soft toys is something that requires a lot of sewing and using fabrics,” he said. “I’m used to conceptual projects, but this was manufacturing something physical, so that was very new to me, and I enjoyed it.”

Noam Arenstein, a fourth-year mechatronics engineering technology major from Scarsdale, N.Y., applied to Studio 930 for the experience of working on a multidisciplinary team in preparation for entering the workforce. Later, he learned he could earn co-op credit from participating in the program, as well.

Studio930 introduced Arenstein to the process of design thinking and prioritizing the needs and perspectives of the end user and other stakeholders.

“I’ve never worked on a product that is tailored to other people’s concerns,” Arenstein said. “One of the new experiences for me was including empathy when it comes to design.”

Supported this summer by the School of Individualized Study (SOIS), Studio 930 has its roots in the industrial design department. Stan Rickel, associate professor in the School of Design, started the program in 2015 to give industrial design MFA graduates client-driven work experience. When a couple of engineering students heard about the idea and joined the group, Rickels saw how Studio 930 could expand.

“The enthusiasm of the students kept it moving,” Rickel said. “This year, we had 15 students in the program from five different colleges and eight different academic programs.”

The collaborative, client-based program also draws like-minded RIT professors whose interests complement and sometimes overlap. Engineering professor Dan Phillips, for instance, helps recruit students and elicit college support. He also solicits and assesses challenges from participating community partners.

The bandage dispenser designed for Rochester Regional Health is one example of students brainstorming concepts with advice and feedback from the client, a strategic partner in the RIT-RRH Alliance.

Studio 930 is both a program and a community that revolves around collaborative and interdisciplinary teamwork focused on accessibility and healthcare, according to Dan Harel, the studio’s manager and adjunct professor of industrial design.

Studio 930 operates from the SHED, giving students easy access to makerspaces, materials, and meeting rooms. The facility, which opened in 2023, provides a common space for the Studio 930 teams, which, in the past, had been scattered in workshops across campus. Offering the program in the SHED has made a difference in the quality of the students’ projects, Harel said. “You get bigger ideas when you have the room to spread out and play with different processes.”

Proximity to different technology, from textiles to 3D printing, in one facility encourages creative thinking, he said.

“We were able to generate more and quicker prototypes using materials that are available here, or that we purchased, and everything went faster,” Harel said. “The students were really inspired by the open environment and interactions with visitors. You know, people come and see what you’re working on, and it’s really encouraging to students.”

Along with SOIS, Studio 930 was sponsored by the industrial design department within the College of Art and Design, the College of Engineering Technology, the Kate Gleason College of Engineering, and the Waldron Rise Foundation.

Latest All News

- Tiger Tutor Team prepares for second year with Rochester studentsLily Yengo loves math, kids, and fellow nerds. The fourth-year mechanical engineering student participated on the Tiger Tutor Team this past spring semester, working with accelerated fifth graders in the Rochester City School District to ensure they retain their love of math. This summer, Yengo is helping to enhance instructional materials—adding and testing new activities and problems-- and providing improvements to the overall process of recruiting and training new tutors for the upcoming academic year. Based in the industrial and systems engineering department, the Tiger Tutor Team began in the 2024-2025 academic year, and more than 60 RIT students tutored five eighth-grade classes and one group of talented fifth graders at three Rochester schools: Loretta Johnson Middle School, School of the Arts, and No. 12 School. The goal was to keep students in accelerated programs excited about, and engaged in, math, as well as improve passing rates for those taking the New York State Regents exams. “I love working with kids. I love math, I’m a huge nerd and so working with these super smart kids who are huge nerds—and I mean this in the most loving way possible—they were there because they wanted to be there. They wanted to learn algebra and trigonometry in their free time. So, we taught them,” said Yengo, who is from Skaneateles, N.Y. Yengo is currently on co-op in Rochester for the DDS Companies, creating base maps of underground utilities to be used in natural gas main installations. She assesses historical records and current photos to compile a map with all the necessary information above and below ground. Yengo talked about the tutoring work and her inspiration for teaching. What is the Tiger Tutor Team? And who were the students you worked with? It’s very new. Dr. Katie (industrial engineering department head Katie McConky) began a partnership with the Rochester City School District and invited engineering and math students to volunteer. She said if you like working with kids and if you like math you should be a Tiger Tutor, and I was like yeah… perfect! There were about 15 of us that worked with the fifth-grade students in groups of three or four. What are you doing this summer to support the program for the upcoming academic year? Sometimes it’s trial by fire and you just need to throw it together and see what works and what doesn’t. We didn’t have a curriculum per se, so my job now is to do that work so that next semester’s tutors are prepared. Everything will be ready. I may not have known how to teach someone the quadratic formula, but my job over the summer is to prepare a guide for the tutors with worksheets and answers, just to make everything more streamlined. Coming up with math problems on the fly is really hard. Why is work like this important for you, your peers, and the fifth graders? For me, at RIT, I am a student, I am there to learn and I’m trying to soak up as much calculus as I can, because it is really hard. But with the kids, it is such a different age demographic. It’s fun to talk to them and these kids are fun. As someone who grew up in public schools in situations similar to them, I loved learning and would have loved to have a program like this—a program to push the boundaries of what I knew. To succeed in something that challenging is rewarding—for them and for us. And you can tell that they know that is really hard, and that’s why they like it too. When we do algebra together, they are asking questions, talking to each other, they are showing each other their work, it is a bigger conversation. How did you prepare for fifth graders who want to take eighth-grade advanced math classes? I’ve got to shout out to my mom. She was a teacher her whole life, now she is a principal. I have always been around kids. I’ve gone to her classroom after school and hung out with her and whatever kids she was teaching at the time. I’ve taken a lot from her to do this job. We’ve probably talked about this job more than any other that I’ve had because she cares about algebra curriculums, that’s her thing. She loves teaching. I learned the most from my mom about this. To learn more The pilot year saw significant gains in mastery rates for students taking the Algebra Regents exam, according to the RCSD Department of Math. RIT’s Tiger Tutor Team is seeking additional tutors and is expecting to expand to include both fifth and sixth graders from School No. 12. The time commitment for tutors is approximately two hours per week. To get involved, contact Professor Katie McConky at ktmeie@rit.edu.

- App blends history, technology, and student talent in new tourism initiativeA collaboration between RIT and the Finger Lakes Visitors Connection is about to change how people experience local history in Ontario County, N.Y. The Finger Lakes Virtual Museum app—developed primarily by students and set to launch publicly this fall—is a digital storytelling platform that combines historical content with technology to create immersive visitor experiences. The idea began with Finger Lakes Visitors Connection, the county’s official tourism promotion agency, which wanted to add “more of the story” to historic markers across the region. Backed by a grant from New York State Empire State Development, the project was brought to RIT’s MAGIC Spell Studios to engage students in real-world development work. “This is exactly the kind of hands-on, real-world experience that students need,” said Diane Linnet, project director, business development and adjunct professor at RIT. “It’s not hypothetical. They’re working with clients, managing deadlines, solving creative and technical challenges, and seeing the direct impact of their work on the community.” A multidisciplinary team of students collaborated over the past year on everything from design and user experience to content creation, and included 2D- and 3D-digital storytelling, augmented reality, photo and video production, and location-based interactive activities. Provided RIT student Jason Salazar Tobar, who was augmented reality developer on the project, used the experience to reflect on the cultural impact of his work. When launched, the app will be accessible through a web platform and as a downloadable mobile app. Visitors to Ontario County will be able to scan QR codes on historic signs and access curated digital content that adds to each location’s story. Jason Salazar Tobar, a fourth-year individualized program major from Mount Kisco, N.Y., served as augmented reality developer, and used the project to continue exploring his interest in how emerging technologies can intersect with art, culture, and live performance. This past March, he and Max Stromfeld ’25 (graphic design) debuted a prototype of the app during a conference in Dubrovnik, co-organized by RIT Croatia. “This project gave me a whole new perspective on the museum world,” said Salazar Tobar. “I started thinking more like a curator and asking deeper questions like, ‘What are we trying to make the user feel?’ It pushed me to go beyond just making something cool and really considering the cultural impact of the experiences I was building.” Linnet added that projects like this are helping to enrich the region’s tourism while preparing students for industry. “We’ve already seen students go into interviews where this project was a major conversation point,” she said. “That’s the kind of return on investment that benefits everyone—students, universities, and communities.”

- Lousto honored with Argentine award for outstanding scientific contributionsCarlos Lousto, Distinguished Professor in the School of Mathematics and Statistics, is a recipient of the 2024 RAICES Award, granted by the Secretariat of Innovation, Science, and Technology (SICyT) of the Argentine government. The RAICES award, or Redes de Argentinos Investigadores, Cientificos y Tecnologos en el Exterior, recognizes distinguished Argentine scientists living abroad who make notable scientific contributions in strengthening science and technology capabilities in their home country. “Thank you to RIT for all the support to perform top research during my already 18 years working here!,” said Lousto. “This award encourages me further to keep working hard.” Lousto was officially recognized with the award at the Consulate General of Argentina in New York in early July alongside fellow honoree Viviana Zelizer of Princeton University. “This recognition is a significant testament not only to Dr. Lousto’s outstanding career and continued global influence, but also to the remarkable depth of faculty talent we have at RIT,” said College of Science Dean Andre Hudson. “It underscores the vital role that international scholarship and collaboration play in advancing the frontiers of science and education.” RAICES awardees are selected by a jury composed of authorities from SICyT, CONICET, and prominent academics. Lousto is a co-director of RIT’s Center for Computational Relativity and Gravitation and has been involved in groundbreaking research on gravitational waves, black holes, and pulsars. He was awarded membership in the Alexander von Humboldt Foundation in 1993, the American Physical Association (APS) in 2012, and received the Bouchet Prize in 2019. He was also recognized with the Breakthrough Special Prize in 2016 for his work leading to the first detection of gravitational waves from the merger of two black holes. He was officially nominated by the US Congress for his research work in 2006 and 2016. He received a Ph.D. in astronomy from the University of La Plata and a Ph.D. in physics from the University of Buenos Aries. He designed the Funes, Newhorizons, and BlueSky supercomputer clusters that perform binary black hole simulations and has authored or co-authored approximately 300 scientific articles in international journals.

- RIT names three new members to university boardRIT has appointed three new members to its Board of Trustees. Jane Elliott ’88 (accounting) is executive vice president and chief human resources officer at NCR Voyix, with decades of experience in accounting, finance, investor relations, and strategy. In her role, Elliott creates and executes the company’s people strategy to support growth objectives. She has also served in the top human resources role at three publicly listed companies. She has served on the RIT President’s Roundtable since 2019 and the Saunders College of Business National Council since its inception in 2022. In 2017, she created the Jane M. Wentworth ’88 Endowed Scholarship in Saunders College. In 2020, she contributed to the Saunders College expansion project. She has also served on the boards of Junior Achievement of Georgia, and Cool Girls, a nonprofit organization dedicated to the self-empowerment of girls living in Atlanta’s most vulnerable communities. Brenda Haynes, a retired oncologist and hematologist, trained at the Albert Einstein College of Medicine and completed her residency, internship, and fellowship at the University of Pennsylvania’s Perelman School of Medicine. While no longer actively practicing, she maintains affiliations with Harvard Medical School and Newton-Wellesley Hospital, and most recently served as an oncologist with New England Hematology and Oncology. She is the parent of a second-year civil engineering technology student at RIT and she serves as a volunteer on a number of nonprofit organizations. Dr. Haynes and her husband, Dr. Adam Koppel, are members of RIT’s Sentinel Society and have been active supporters of the College of Engineering Technology, College of Health Sciences and Technology, and several student project teams. Chance Wright ’18 (photographic and imaging arts) ’19 (MBA) is a serial entrepreneur having founded or co-founded several companies including Wright Productions and Entertainment; ATL/WYO Productions; Skull Diamond and Heart Capital; Chance Wright Photography; and The Shore Foundation, a Rochester-based nonprofit dedicated to improving the community through equal access to technology, while also impacting the environment by shifting the impact of used technology. He has served on the President’s Roundtable since 2020 and the College of Art and Design’s National Council since 2021. In 2019, Chance and his mother, Pamela Mars-Wright, made a significant gift to the School of Photographic Arts and Sciences. In 2021, Wright supported the Saunders College of Business renovation and expansion project. Elliott, Haynes, and Wright will each serve four-year terms on the board.

- Caroline M. Solomon named president of RIT’s National Technical Institute for the DeafCaroline M. Solomon, dean of faculty at Gallaudet University, has been named president of Rochester Institute of Technology’s National Technical Institute for the Deaf and vice president of RIT. She will begin her tenure at RIT/NTID on Aug. 18. View the announcement in ASL An ASL version of the announcement is available. “NTID has revolutionized education for nearly 60 years,” said RIT President Bill Sanders, who began leading the university July 1. “Dr. Solomon brings a deep understanding and appreciation for NTID’s distinctive culture. She has the vision to champion NTID’s legacy while moving it forward for the next generation of students. I look forward to partnering with Dr. Solomon as we continue to advance NTID’s mission and ensure that the college remains a leader for deaf and hard-of-hearing students, both nationally and globally.” Established by the U.S. Congress in 1965, NTID is the first and largest technological college in the world for deaf and hard-of-hearing students. Solomon, who will become the first woman to lead the college in its nearly 60-year history, was raised in Delaware and is the daughter of a former professor at the University of Delaware. She earned a bachelor’s degree in environmental science and public policy from Harvard University and a master’s degree in biological oceanography from University of Washington’s School of Oceanography. She earned a doctorate in marine, environmental and estuarine sciences from University of Maryland. She joined the faculty of Gallaudet University as a biology instructor in 2000 and rose to the rank of professor in 2011. She received Gallaudet’s Distinguished Faculty Award in 2013 and was recognized by the Association for the Sciences of Limnology and Oceanography with their Ramon Margalef Award for Excellence in Education in 2017. She was appointed the dean of faculty in 2024. A renowned scientist and researcher, Solomon has devoted herself to encouraging and nurturing deaf and hard-of-hearing students in STEM fields, and has presented on her research at national and international conferences as well as to RIT/NTID students and faculty. She has developed a database of science-based technical signs in American Sign Language. Solomon, a past participant in the Deaflympics as a swimmer was inducted into the Deaflympics Hall of Fame in 2020. In her new role, Solomon will serve as chief executive of NTID, providing leadership in developing and executing the college’s vision and strategic plan, and is responsible for NTID’s financial operations and budget, enrollment management, academic programs, external and federal relations, and fundraising. “As a Deaf scientist, I’m deeply honored to join the vibrant NTID and RIT community—longstanding national leaders in advancing STEM education for Deaf and hard-of-hearing students,” Solomon said. “I look forward to working with President Sanders and collaborating with students, faculty, and staff to expand pathways in education, employment, and leadership. Together, we will ensure that every student has the opportunity to thrive, lead, and drive innovation across every sector of society.” RIT President Emeritus David Munson initiated the search before retiring June 30. “We are thrilled to welcome Dr. Caroline Solomon to the RIT community as the next leader of NTID,” said Munson. “Caroline brings an extraordinary blend of academic leadership, scientific and technical expertise, and a lifelong commitment to advancing access and equity in education. Her distinguished career at Gallaudet University and her well recognized work in STEM education for deaf and hard-of-hearing students make her superbly qualified to guide NTID into its next chapter.” Solomon succeeds Gerry Buckley, who has served as president of NTID and vice president and dean of RIT for 15 years and will retire Aug. 17. “Dr. Solomon brings with her an outstanding academic and STEM research record and wealth of higher education knowledge and experience,” added Buckley. “I’m so pleased that she will lead NTID into the future, and know NTID is in highly capable hands. I look forward to welcoming Dr. Solomon and her family to Rochester and the NTID community in the months ahead.” NTID offers associate degree programs for deaf and hard-of-hearing students and provides support and access services for deaf and hard-of-hearing students who study in the other eight colleges of RIT. NTID also offers certificates in healthcare interpretation and sign language specialties, bachelor’s degree programs in sign language interpreting and community development and inclusive leadership, as well as master’s degrees in secondary education for deaf and hard-of-hearing students and in healthcare interpretation.

- Game-changer Stephen Jacobs retires after 30 yearsAfter three decades of teaching, mentoring, and pioneering academic and research programs at RIT, Professor Stephen Jacobs is retiring. Jacobs worked as an adjunct faculty member in English and computing before becoming a full-time professor in 1995. As a video game expert, he taught courses in game programming and game design/narrative. Together with former faculty members Andy Phelps and Jeff Lasky, Jacobs wrote the proposal for RIT’s master’s degree in game design and development. Today, RIT’s games degrees are regularly ranked among the top 10 in the country. With RIT’s MAGIC Spell Studios, Jacobs served as one of the original associate directors—focusing on industry relations. He collaborated to produce MAGIC’s first game on the Nintendo Switch platform, called The Original Mobile Games—a partnership with The Strong National Museum of Play and Second Avenue Learning. Jacobs has also served as a steward for all things FOSS (free and open source software) at RIT. He helped create courses and programs on the subject and served as director of the Open@RIT research center. “I’m not a traditional academic,” said Jacobs. “It’s been a pleasure to spend the last 30 years as an RIT professor.” Below, Jacobs shares reflections from his time at RIT. What has your long-term partnership with The Strong National Museum of Play meant to you? I’ve been a Scholar-in-Residence since 2007. In that role, I’ve been able to serve as a member of exhibit design teams, co-create an online course in game design history that was nominated by students for an edX award as a best course, and help bring conferences to Rochester—like the upcoming 2025 Conference on BIPOC Games Studies. That kind of work, over the years, led to a Tourism Achievement Award from Visit Rochester. We also enjoy bringing classes to The Strong every year. This year the “final exam” for my History and Design of Pinball class was to demo their analog and digital games at The Strong as part of a museum-wide pinball day we co-organized. I’ve also been working with them around my research on the Jewish History of the Toy and Games Industries in Germany and the U.S, which we’re developing into an exhibit for 2026. Why do you champion open source for social good? I was attracted to this world through the One Laptop Per Child initiative. They were providing low-cost laptops to children in developing countries. In 2009, I created an honors seminar for our students to make educational games for the One Laptop Per Child community. Over 16 years that initial course grew into an immersion focusing on humanitarian open software development and an interdisciplinary minor—the only one of its kind in the world. It also led to our Open@RIT center to support faculty, staff, and students’ Open research and work. That center had us lead several workshops, join the Linux Foundation, and receive more than $1 million in awards to support its work over four years. I received the Provost’s Excellence in Faculty Mentoring Award in 2019-2020 (in part for this work) and the PI Millionaire award in 2023 for grants from the Alfred P. Sloan Foundation. Alberto Bobadilla Jacobs enjoys joining students on the travel-enhanced courses. This year in Japan, students immersed themselves in the culture and visited a Japanese game studio. How have you encouraged students to make lifelong connections outside the classroom? Video games are an international industry, and it’s important to have international experiences on your résumé. I began teaching travel-enhanced courses—ones that meet on-campus for a semester with international travel before or after the on-campus work—in 2014. These courses established a model of spending a week in one town (in Paderborn, Germany for this one), holding a game jam over the weekend with the German students (a weekend-long, video game creating marathon), and then traveling elsewhere in country for a week to visit cultural sites and game studios. I taught this again in 2017 and 2019. In 2018, I replicated the Germany model in Japan. We worked with Ritsumeikan University and the Kyoto Computer Gakuin, a long-time partner with RIT in international education. This year, in addition to the course’s regular visits to the CyberConnect2 video game studio and Hiroshima, we were able to attend World Expo in Osaka. As a result of this course, the vice president of CyberConnect2 and the global section chief of human resources for the company will be visiting RIT and The Strong to recruit our upcoming graduates to work in Japan and to explore the exhibits and research assets at The Strong.